Coal Gas--The Original Gaslighting

Coal Gas--The Original Gaslighting

Coal gas--later called town

gas-- is produced by burning crushed lumps of coal in an oxygen starved

atmosphere to produce methane and hydrogen, both of which burned brightly, as

well as small amounts of nonflammable but poisonous gases such as carbon

monoxide, carbon dioxide and nitrogen.

Peale's museum was so

successful in lighting for night time exhibits a consortium of financiers

including Peale formed the Baltimore Gas company to illuminate the city's

streets and, ultimately sell gas to private homes.

Over the following years most urban centers set up town gas plants and laid thousands of miles of

gas lines to both light the streets and some wealthy homes. It would not be until 1882 that Thomas Edison would provide electric power to homes and offices (in NY City, near Wall Street to impress investors.)

Gas lighting and heating

had a tremendous impact on society and manufacturing businesses could now run

plants at night. Workers on 12 hour shifts kept textile mills and iron smelting

plants going day and night. Steam powered machinery could now be run around the

clock.

Running

machinery constantly required much more oil to keep parts

lubricated. Whale oil was ideal for this task so the creatures were

hunted to near extinction while the cost of whale oil rose beyond the means of

the average family.

The stereotype of slaves

mostly picking cotton in the fields or serving ham and grits to the white

masters in the "Big House," is false. A better description is

"any hard, and dangerous job was handled by slave labor."

Municipal gas companies

bring about a look at one of the other widespread uses of enslaved people--coal

mining and working in gas factories.

A town located near a

deposit of coal was considered a great location. Transporting coal over a

short distance to a gas plant was inexpensive.

Coal was mined by slaves

under white supervision. Local slave owners were happy to rent out their

slaves to local gas companies or coal mines. Cotton yields were poor by

this time in the Southeast, so renting out their excess labor was

economically more attractive than selling their slaves to new plantations in

Alabama or Mississippi. Owners suffered no loss if a slave were

killed or badly maimed in a mining accident--the coal company had insured

them.

Plus,

if a slave survived several years as a miner, the coal company paid the owner even

more per year because the slave was now considered experienced labor.

If the mines had all the

labor they needed, a slave owner could rent his slaves to the gas company

itself. Men in bricked underground vaults shoveled coal into the low

oxygen furnaces 12 hours a day to mass produce gas.

There was only one aspect

of gas companies that gave upper class whites in the South concern.

Running the gas plant

itself, controlling the distribution, and repairing or replacing equipment

required literate skilled labor. It required White labor from the North.

The spectacle of well-paid

White labor in front of Southern poor Whites was a social danger.

Farming, storekeeping along with professional jobs such as lawyers or

doctors were the only jobs besides slave catching socially considered

respectable work for White men. In the South, common labor was

strictly the providence of slavery.

Gas in DC

May 29, 1857

ABOUT GAS—The Washington Gas Company in manufacture of gas

for the use of this city and Georgetown, consume an average of 30 tons of coal

daily. This gives an average of 210 tons per week. Each ton of coal produces

about 20,000 cubic feet of gas, which in one day’s manufacture, amounts to 600,000

cubic feet. The amount per week is, according to this, 4,200,000 cubic feet which

is consumed as fast as made. The number of men employed by the company is 38,

and they receive from $1.00 to $1.75 per diem for their labor. The cost in

material and manufacture per week amounts to at least $1,800, and is probably

more than that: perhaps $2,000 to $2,500 per week.

The company receive nearly all the coal used in the manufacture

of gas from Port Walthall, Virginia. This is considered the best gas for the

purpose of making gas. The English bituminous coal which is partly used by the

company, is preferred to the native coal. One pound of English coal will

produce five cubic feet of gas, while the amount f Port Walthall material will

produce on three and a half cubic feet. The quality of the gas from the former

is also considered superior to that obtained from native coal.

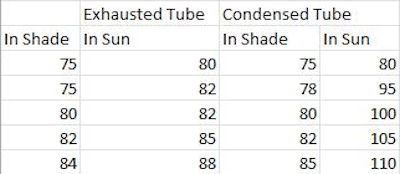

London, England August 24, 1860

NEW GAS IN LONDON—It is stated in late London papers that

the new “line light gas,” which was promised to supersede the present mode of

gas lighting, has been tried on the bridge at Westminster, and with great

success. The light is of dazzling brilliancy,

a single jet being equal to forty argand, or eighty fish tail gas burners, or

as many as 400 wax candles, whilst its brilliance may be increased by augmenting

the quantity of gases supplied in its manufacture. It was understood, when the

invention was first discovered, that the gas would be cheaper than that now in

use, but at present the only thing stated of it is, that it is immensely superior

to the ordinary form of gas light.

June 15, 1852 NY Times page 1

Gas lamps to be installed Along with Oil Lamps

The Board of Assistants has approved:

Resolution adopted—To have Broadway from forty-sec0nd street

to fifty-ninth, lighted with gas.

Resolutions Adopted—That the pump on Cherry Street near

Clinton-street, be repaired; that Duane-street from Broadway to Centre-street,

be lighted with gas…..that the Commissioner of Lamps report why the lamp-posts

are not set in One-Hundred and Twenty-second -street; that Forty-ninth-street,

from Eight to Ninth-avenues, be regulated in accordance with the new grade; ;Forty-sixth-street

from the Tenth-avenue to the Hudson River, be lighted with oil; That Tenth-avenue

from Forty-second to Forty-eighth-streets, be lighted with oil…

Coal Gas Competition May 26, 1866 NYT page 5

GAS FROM PETROLEUM—A Company has been formed in this City

for the purpose of supplying the public with gas for lighting and heating purposes

manufactured from crude petroleum. It is claimed that the gas has nearly three

times as much illuminating power as coal gas, that it is entirely free from

odor, and can be supplied for 40%, less than coal gas at present prices. The

company have purchased all the patents for manufacturing gas from petroleum,

and they propose to commence operations so soon as the necessary capital, $3,000,000,

is raised.

They have a grant from the Corporation to lay pipes and

mains in all the streets, avenues, lanes and public parks within the City

limits. Within a few weeks the public will probably be afforded an opportunity

of judging of the difference in illuminating power between petroleum and coal

gas.

Comments

Post a Comment