Fiat Lux!

Fiat Lux!

There is

darkness behind light. We take it for granted—lighting is cheap, easy, and

quick. It was not always so.

In a survey carried out by a newsmagazine in the late 1850s, people were asked to list the most important and useful things invented in the previous two decades. At the top of the list: matches.

Matches made starting light so much easier and faster. They were referred to at the time as "lucifers" from the devil angel's name which means in Latin "bringer of light."

Now, with lucifers, there was no more careful tending of a fire not to go out, or the difficult

journey to a neighbor’s farm for a bit of fire to carefully take home. Candles, lamps, and cigars could now be

lighted anywhere. Matches were so cheap they were available to all levels of

society. Originally made from phosphorus, matches could burst into flame with

the slightest friction—in a pocket, scuffed on the floor, or simply dropped. Not

surprisingly, the number of accidental fires increased dramatically. “Children playing with matches,”

became a commonplace entry in insurance claims whether true or not, while

newspapers pleaded “Parents, teach your children not to play with matches!”

Matches were

made at terrible human cost, mostly using child labor. Working with phosphorus 12 hours a day six

days a week quickly affected children. Their

clothes and even their breath glowed in the dark. It made them stink. Worse, it caused the gums

on their jaws to rot and fall away, leaving them in great pain and with a

gruesome glowing smile and sometimes literally jawless.

Phosphorus

reached the match manufacturers’ buildings, having already left a trail of

misery. Phosphorus was extracted from guano, bird dung built up over millennia

on small islands off the coast of Peru. It

already had a market since guano was a very popular fertilizer sold to farmers

by the ton. The islands were remote and very small, generally a few hundred

yards long and wide. Slaves, often kidnapped Chinese, used pick axes and

shovels to dig up large, crystalized chunks to load ships that would call to

collect it every week or so.

Matches & Candles for Wholesale

Jackdaws Shouldn't Play With Matches!

Candle

making in the early 1800s was not the easy hobby it is today using microcrystalline

wax and other oil by products. Most candles then were made of tallow—hardened

pork or beef fat. To efficiently use all the fat from a recently slaughtered

hog or cow required an operation of several days. It was a domestic chore despised by many women.

Wicks had to be spun; a large amount of firewood gathered; racks to hang

partially dipped candles on made; chunks of fat cut to be boiled down and

refined in large kettles over several days.

In the end, the housewife was rewarded with dozens of candles giving off

as much smoke and foul odor as they gave dim light.

That’s where

turpentine comes in. I had been puzzled

compiling clippings for this blog by the numerous ads in newspapers,

particularly in the eastern Carolinas, for “turpentine stills.” Turpentine was

made from refined pine sap. The Piedmont and Coastal Plains of the Carolinas

were covered with pine forests. For more

than a century the region had been known as a center for “naval stores,” tall

straight masts and spars as well as lumber, turpentine and tar derived from

pine sap. Pine tar was an excellent

water barrier. Wooden ships were

practically encased in it. No wonder sailors were often called “Jack Tars.”

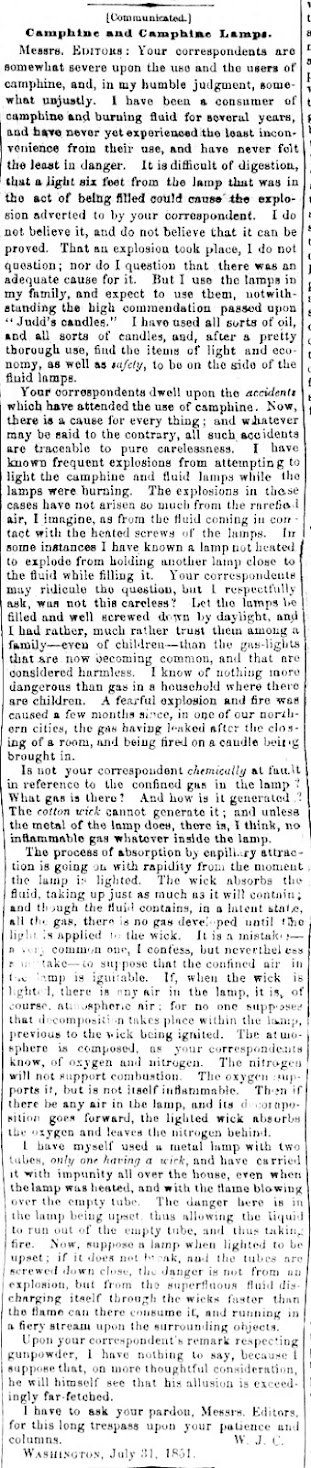

In the 1830s

it was discovered that turpentine mixed with alcohol created a brightly burning

substance variously called “camphine” or “camphene.” Most people referred to it

as “burning fluid.” It was cheaper than candles and gave off more light. It was

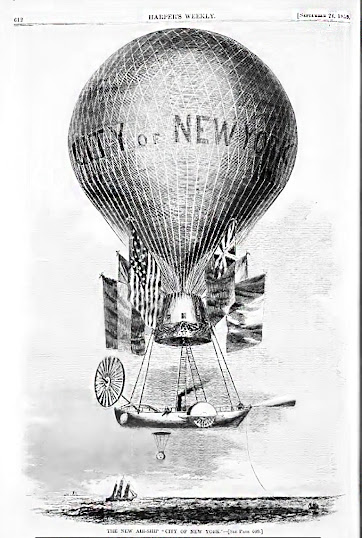

far cheaper than whale oil and gave off almost as much light. It was not as bright as gas light or as inexpensive

but only factories and the rich and emerging middle class could afford the upfront

expense of having gas lines and fixtures installed.

Turpentine Tax

Notice; far more turpentine than rice or cotton produced in North Carolina

At the same

time whale oil was becoming much more expensive. Not only had over hunting made whales rarer,

but new factories, mainly steam powered textile mills, found whale oil the

ideal lubricant for their machinery. Gaslight

meant factories could run day and night.

As they churned out hundreds of yards of cloth, they certainly could

outbid anybody else for whale oil.

All that

cloth had to go somewhere—and it did--into the new industry of ready-made

clothing. Mr. Singer’s sewing machine was not yet widespread, so sewing was

still the hand work of women. Sewing

men’s shirts was a respectable way to eke out a living. After a woman’s chores of cooking, cleaning,

and child care were done if a woman worked all night, she might be able to

finish two or even three, shirts. If her

shirts were of good quality, she would be paid four cents each.

Piece work

sewing at night required good light and it had to be cheap light.

Camphene

seemed to be the right product at the right price at the right time.

Except that:

It was

dangerously explosive.

Camphene Lamp

Handled

carefully and burned in the lanterns specifically designed for it, camphene was

relatively safe. With the decline in use

of whale oil, second hand whale oil lanterns became cheaper. They would burn

camphene, too. Knocked over or even

jarred roughly, camphene instantly exploded into a fireball.

Overwhelmingly,

the victims were women and children and not just the ones in the immediate area

of explosion. Camphene use was

widespread in ramshackle tenement buildings.

One explosion could set the building on fire and the fire would spread

as it consumed more camphene lanterns.

Rather like

mass shootings today, after each tragedy newspaper editors and politicians

would inveigh against the cynical businessmen selling camphene. And then nothing would change. There was no

real alternative.

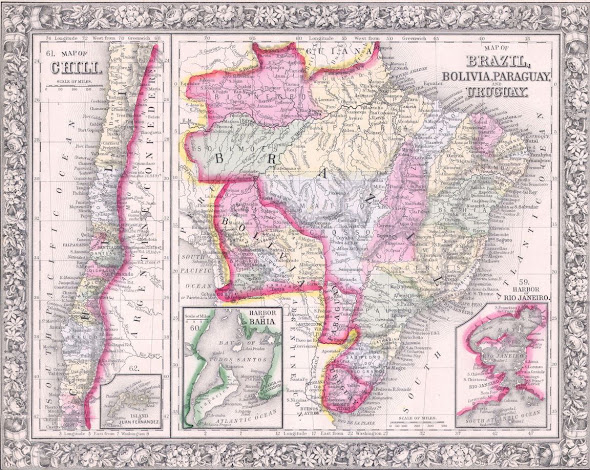

By the late

1850s it is estimated North Carolina’s pine woods provided 90 percent of the

nation’s light.

Harvesting

turpentine was much more profitable than wringing cotton out of long depleted

soil. Slavery in a turpentine operation was different than that of a

plantation—but it could be no less brutal.

Slaves were

given axes or machetes and taken to an area of woods and put to hacking open

areas –called “boxes” --at the base of pine trees. Then, cuts would be made on the tree trunk

above the box. Months later, slaves

would collect the pine sap and take it to a turpentine still. The stills were

generally located near a stream or river so barrels of turpentine and refined

tar could be easily loaded onto barges and floated downstream to ports such as

Wilmington. From there, it would be

shipped north to mixed with alcohol distilled from Midwestern grain and the

result sold to the poor in the northeast and all over the country.

Turpentine

production was viewed as way to make a slave economy possible again. At the time, the chief cash export was

breeding slaves to be sold to the new plantations in the Deep South.

The Civil

War cut off turpentine to the camphene

trade. Then the Federal government

dramatically raised the tax on alcohol to help fund the army. And an alternative to camphene now

existed. Kerosene derived from the new

oil fields of Pennsylvania was both cheaper and readily available.

By the end

of the war, the light of camphene was extinguished.

My thanks to

Jeremy Zallen, associate professor of history at Lafayette College. His book “American Lucifers-the Dark

History of Artificial Light 1750-1865”

(UNC Press 2019) pointed me in the right direction to look further into

newspapers of the times. His overview

explaining how various events and social transitions affected the economics of

everything from candles to coal mining is superb.

Camphene Explosion

Gas does not mean coal gas or oil gas in ad above

Another Camphene Explosion

And Let There Be Light!

Comments

Post a Comment